28 Guihua Road, Zhonglou District, Changzhou,Jiangsu

PET film is a type of plastic called polyethylene terephthalate film. It is strong and clear. PET film is a thermoplastic polymer. Manufacturers like PET because it is tough. It can handle heat and bends easily. There are different kinds of PET film. Many industries use PET film. The food and drink industry uses PET film for packaging. It helps keep food fresh and safe. Electronics companies use polyethylene terephthalate for insulation. They also use it in screens. Other industries use PET film for labels and more. In 2024, the global PET film market was worth over $37 billion. Packaging is the biggest part of this market.

PET film is tough, see-through, and can handle heat. This makes it great for packaging, electronics, and labels. Its clear look helps products get noticed. Its strength keeps food, medicine, and electronics safe from harm. PET film does not get damaged by chemicals, heat, or UV light. This helps products last longer and stay safe. Recycling PET film saves energy and cuts down on pollution. It also helps the environment and green packaging. Many industries use PET film because it is strong and safe. It also makes products look better and protects them.

PET film is known for being very tough. It can handle pulling and stretching better than many other plastic films. This means it does not break easily when pulled. PET film keeps its shape even if the temperature or humidity changes. The table below shows how PET film and polyimide film are different in some ways:

Property | PET Film | Polyimide Film |

|---|---|---|

Tensile Strength | 55-75 MPa | 120-220 MPa |

Flexural Modulus | ~2.5 GPa | ~4 GPa |

Transparency | Clear | Not clear |

PET film is strong and stiff enough for many packaging jobs. Polyimide film is stronger, but PET film is both strong and clear.

Many companies pick PET film because it is very clear. PET film lets more than 90% of light pass through. This makes it easy to see what is inside the package. PET film is also used for screens and panels because it is so clear. Its smooth and shiny surface looks nice. In screens, PET film helps make pictures look sharp and bright.

PET film’s clear look helps products stand out and be easy to see, which matters for packaging and electronics.

PET film does not get damaged by many things. It can handle oils, fats, weak acids, alkalis, and most solvents. PET film can also take heat from -70°C to 150°C and still work well. This is good for places where the temperature changes a lot. PET film blocks some UV light, so it helps protect things from the sun. It does not soak up much water, so it stays steady and works well.

PET film’s ability to resist chemicals and heat makes it a good choice for factories and electronics.

Its UV resistance helps products last longer outside.

PET film has a special structure that makes it stiff and strong. It is not as bendy as some other films like PVC or EVA. But this stiffness helps PET film keep its shape when heated or formed. PET film does not shrink or bend out of shape easily, which is important for careful work.

PET film is flexible enough for most packaging and electronics, but not for things that need a lot of stretching. Its strength and steady shape make it great for fancy packaging, electronic parts, and medical tools.

PET film is important in packaging today. Its special features make it popular. Many companies use PET film to keep products safe. It helps food stay fresh and clean. PET film also makes packages look nice. Below, you will learn how PET film works in food packaging, blister packs, and flexible films.

PET film is used a lot for food packaging. It keeps food fresh and safe. The film is clear, so people can see the food inside. PET film lets about 84-86% of light through. This makes food look good in stores. The film blocks gases and moisture. This stops food from going bad or drying out. PET film also protects food from germs and other bad things.

Manufacturers pick PET film because it is strong. It does not rip or tear easily. PET film keeps its shape when shipped or handled. It is light, so shipping costs less. Less material is needed, which helps the environment.

PET film keeps food safe by blocking germs. It helps food stay fresh longer. It also helps cut down on food waste.

Many companies use PET film in packages with many layers. These layers block oxygen and water vapor. Oxygen and water vapor spoil food. Some PET films have special coatings. These coatings fight germs and keep food safe. For example, antimicrobial agents can be added to PET film. They stop germs from growing on foods like meat and cheese.

Rules say PET film for food must be very safe. In the United States, the FDA checks PET film. They make sure it does not let bad things into food. In Europe, the EFSA does this job. These rules help keep food safe for everyone.

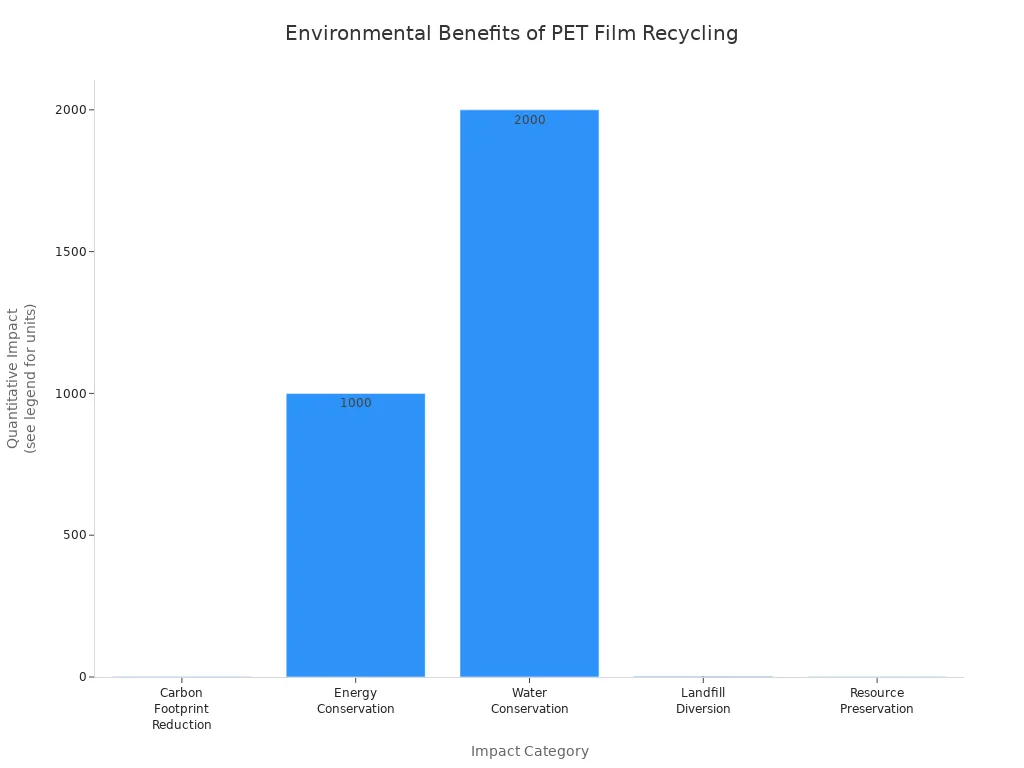

PET film is good for the planet. It can be recycled and made with recycled stuff. Recycling PET film saves energy and cuts pollution. The chart below shows how recycling PET film helps the earth:

Blister packs use PET film to protect medicine and small items. The film makes a clear, strong cover over each thing. People can see the product but it stays safe from dirt, water, and air. PET film in blister packs meets strict safety rules from groups like the United States Pharmacopoeia and European Pharmacopoeia.

Drug companies trust PET film for blister packs. It keeps medicine safe and stable. The film blocks oxygen and water. These can hurt pills or capsules. PET film works well with child-proof and tamper-proof designs. This helps stop accidents and shows if the pack was opened.

PET film in blister packs lets you see each dose.

It gives strong protection from oxygen, water, and dirt.

The film helps with unit-dose packs, so mistakes are less likely.

PET blister packs are light and can be recycled, which helps the planet.

Making blister packs from PET sheets gives great protection and clear packaging.

PET film in blister packs often has recycled material. This helps companies follow new rules about being green. The film can be recycled again, so it fits with circular economy ideas.

Flexible packaging films made from PET have many benefits. They are better than PVC or polypropylene. PET film is safe and does not have toxins. It does not release bad chemicals like PVC. PET film looks nice, with bright colors and sharp prints.

PET film is stronger and better for shaping than PVC.

It can be recycled and is safer for the earth than PVC, which has heavy metals.

PET film costs about 20% less than PVC and is worth more when recycled.

PET film is tougher than polypropylene and resists holes better.

PET film blocks more and handles heat better, so it is good for hot packaging.

Flexible packaging films made from PET keep products safe when shipped or stored. The film does not tear or get holes easily. Packages stay safe. PET film is good for tamper-proof seals and surface protection. Many snack bags, pouches, and wraps use PET film. It keeps food fresh and looks nice.

PET film helps the planet in flexible packaging films. Recycling PET film cuts waste and saves resources. Studies show recycling PET film can lower global warming by up to 90% compared to making new plastic. PET film stays strong and clear even after being recycled many times.

PET film in flexible packaging films helps companies reach safety and green goals.

PET film is great for packaging because it is safe, strong, and good for the planet. Its clear look, strong protection, and ability to be recycled make it better than other plastics. Companies use PET film to keep products safe, make them last longer, and help the environment.

PET film is important in today’s electronics. It is used because it is strong and clear. PET film helps protect parts inside devices. It is used for insulation, displays, and circuits.

PET film keeps electricity from leaking in devices. It is used to protect battery cells and wires. PET film wraps coils in electric car motors. It does not crack or soak up water. This keeps devices safe. PET layflat tubes cover battery cells in high-voltage batteries. PET spiral wound tubing holds wires and keeps them safe from damage. Non-woven PET thermal insulation is used in motor coils and other products. Needled felt PET helps keep appliances like fridges and air conditioners safe. PET polyshrink film makes high-voltage coils tighter and more stable.

Main Uses of PET Film in Electronic Insulation | Why PET Film Works Well |

|---|---|

Insulation, battery cell protection, wire insulation, coil wrapping for EV motors | Strong, good insulation, does not crack, does not soak up water |

PET layflat tubes for battery cell protection | Strong, protects from electricity, does not wear out, can be made in different sizes |

PET spiral wound tubing for wire holding and protection | Does not tear, protects from chemicals and heat, strong |

Non-woven PET thermal insulation for electrical laminated products and motor coil wrapping | Strong, lets air through, does not tear |

Needled felt PET for thermal insulation in appliances | Handles heat, strong, does not wear out, good insulation |

PET polyshrink film for compaction in high-voltage coils | Makes coils tight, stays stable when heated |

PET film is used in screens. It is very clear and smooth. This helps screens show bright, sharp pictures. Anti-reflective PET films cut down glare. They help people see screens better. PET film does not scratch or get damaged by chemicals. This helps screens last longer. PET film is used in smart windows and touch screens. Some PET display films have special glue and layers to protect screens.

PET film helps screens look clear and stay strong for a long time.

PET film is used in flexible circuits and capacitors. It keeps electricity inside and does not change shape with heat or water. PET film is a base for copper foil and other layers. Coverlays made from PET keep circuits safe from water and damage. PET film is also used in control panels and touch pads. BoPET film is a stronger kind of PET. It can handle more heat and is used in audio devices and capacitors.

The PET electronic film market is getting bigger. More people want smart devices and electric cars. Flexible circuits are also popular. PET film can be recycled and is better for the planet. This helps more companies use it in electronics.

PET film is used in many industries. It is strong and clear. It does not get damaged by chemicals. This makes it good for tough jobs. Companies use PET film for products that must last. PET film also helps products look nice.

PET release liners are important for sticky tapes and laminates. They are strong and do not break easily. PET liners do not soak up water or get ruined by chemicals. Many industries use PET release liners. These include car makers, electronics, and builders. Medical companies pick PET liners because they are safe for people. They can be cleaned with heat. PET film works for one-sided and two-sided release liners. Two-sided liners help stick things together better. PET liners last longer than paper liners. They do not get wet or tear as easily. New coatings like silicone make PET liners even better. They help PET liners work in hot places.

PET release liners are used in:

Sticky tapes

Medical tapes and bandages

Car parts

Electronics factories

PET film keeps surfaces safe from scratches and dirt. It is very strong and does not stretch or rip. PET film stays flat and clear in hot or cold places. It does not get ruined by most chemicals. PET film blocks sunlight and does not soak up water. It keeps its shape for a long time. Companies use PET film to cover screens and panels. It protects equipment when shipping or putting things together.

PET film is tough and clear. It helps protect important surfaces in factories and labs.

PET film is used for labels on many products. It is strong and does not get ruined by water or oil. PET labels can handle hot and cold places. They stay easy to read and do not fall apart. PET film is smooth, so glue sticks well. It is good for printing clear words and pictures. PET labels come in shiny white, dull white, and silver. They are used for safety and product names. PET film helps labels stay bright and colorful for a long time.

Label Feature | PET Film Advantage |

|---|---|

Durability | Does not tear or fade |

Chemical Resistance | Handles oil and cleaners |

Print Quality | Smooth for clear printing |

Temperature Range | Works inside and outside |

PET film labels are found on cleaning bottles, machines, and medical tools. They help products follow safety rules and look neat.

PET film is strong and clear. It does not get damaged easily. Many industries use PET film. It helps keep food safe. Electronics and labels use PET film too. PET film helps products last longer. It also makes them look nice. New technology makes PET film even better. Smart layering and nanotechnology help PET film improve. Experts think PET film will be used more. The global market for PET film will grow. PET film helps make things safer and smarter. It also helps protect the planet.

PET film is strong and clear. It does not tear easily. It can handle heat well. Companies pick PET film for packaging and electronics. They also use it for labels. PET film helps keep products safe.

PET film can be recycled. Many companies use recycled PET film. Recycling PET film cuts down on waste. It also saves energy. PET film helps make packaging and industry more eco-friendly.

Coated PET film is used for labels and covers. It is also used for release liners. The coating gives extra features. It can stop scratches or help printing. Many industries need coated PET film. Medical, electronics, and packaging companies use it.

PET heat transfer film puts designs on fabrics. Clothing makers use it for logos and pictures. The film works with high heat. It keeps colors bright after washing.

PET reflective film bounces light back. This helps people see things better and stay safe. Road signs and safety gear use PET reflective film. Advertising displays use it too. The film stays bright and strong outside.

content is empty!