28 Guihua Road, Zhonglou District, Changzhou,Jiangsu

Views: 0 Author: Site Editor Publish Time: 2025-08-20 Origin: Site

PET film, called polyethylene terephthalate, is a useful polyester material in packaging. Makers produce this film with aromatic rings and ester groups. These parts make PET film water-resistant and strong. PET film is flexible for packaging. It is used a lot in food, drinks, and medicine. The worldwide PET film market was about USD 43.1 billion in 2023. This is because PET film blocks moisture and can be recycled. Changing the surface of the film makes it work even better. This helps PET film in more advanced uses.

PET film is a strong and clear polyester. It is used a lot for packaging food, drinks, and medicine. It keeps out moisture and can be recycled.

The film has a special chemical structure. Biaxial stretching makes it tough and flexible. It can resist heat, chemicals, and electricity.

PET film protects products by blocking oxygen, water, and germs. This helps food and medicine stay fresh for a longer time.

PET film can be recycled. This helps make packaging better for the environment. It helps companies cut down on waste and reach green goals.

PET protective film also covers electronics, screens, and industrial parts. It keeps them safe from damage. This makes PET film useful in many industries.

PET film is a kind of polyester used in many packages and factories. People make this film by joining ethylene glycol and terephthalic acid. This makes a strong, light, and clear plastic. PET film is a thermoplastic. It gets soft when heated and hard when cooled. This helps with making and recycling it.

In science and factories, PET film is liked for its high melting point. It melts between 245°C and 265°C. This makes it good for food and other tough jobs. The film’s density is about 1.38 g/cm³. Its tensile strength is between 55 and 75 MPa. These numbers mean PET film is tough and lasts long. It is clear, strong, and keeps out water and chemicals. That is why it is used for packaging. PET film can be recycled, which is good for the planet.

Note: PET film comes in many grades for different jobs. Biaxially oriented polyester film is common in packaging. It is stronger and clearer than other types. The table below lists some grades and what they do:

PET Film Grade Type | Intrinsic Viscosity Range (dL/g) | Description/Context |

|---|---|---|

Biaxially Oriented Film Grade | 0.60 – 0.70 | Used for packaging films |

Thermoforming Sheet Grade | 0.70 – 1.00 | Used for forming rigid packaging sheets |

PET film has special features that make it different from other plastic films. The table below shows some main differences:

Characteristic | PET Film | Other Plastic Films (e.g., PE) |

|---|---|---|

Tensile Strength | High (55 - 85 MPa) | Lower (7 - 37 MPa) |

Melting Point | High (250 - 260 °C) | Lower (115 - 135 °C) |

Transparency | Transparent | Translucent or opaque |

Rigidity and Hardness | Rigid and hard | Flexible and softer |

Barrier Properties | Superior against moisture/gases | Limited barrier performance |

Applications | Food packaging, beverage bottles | Flexible packaging, durable films |

PET film is a semicrystalline thermoplastic polyester. Its chemical structure has repeating terephthalic acid and ethylene glycol units. These units make long chains joined by ester links. The structure has aromatic rings for stiffness. Ester groups give flexibility and help resist chemicals.

The way PET film is built changes how it works:

Molecular Weight: Bigger molecular weight means longer chains. This makes the film stiffer and harder.

Branching: PET film has little branching. The chains are straight. This lets them pack close and makes the film stronger.

Crystallinity: PET film has both crystal and non-crystal parts. Crystal areas stop bending and add stiffness. Non-crystal areas make the film tough and able to take hits.

Orientation: When making the film, it is stretched two ways. This lines up the chains. It makes the film stronger, clearer, and better at blocking things.

Aspect | Description | Effect on PET Film Performance |

|---|---|---|

Molecular Weight | Longer polymer chains and more entanglement | Increases stiffness and rigidity |

Branching | Minimal branching leads to linear polymer chains | Enables closer molecular packing and stronger intermolecular forces, enhancing stiffness |

Crystallinity | Higher crystalline regions resist deformation | Increases rigidity and stiffness; amorphous regions add toughness and impact resistance |

Stretching/Orientation | Biaxial stretching aligns polymer chains | Increases stiffness, strength, and barrier properties |

Molecules in PET film interact in special ways. Carbonyl and hydroxyl groups help with chemical resistance and strength. Catalysts used in making the film can change these interactions. This changes how the finished film works.

Making PET film has a few main steps. First, people make the PET resin. Then, they form the film and finish it.

Polymerization: Makers mix terephthalic acid (or dimethyl terephthalate) with ethylene glycol. This happens at high heat (200–290°C) and uses catalysts. The reactions are called esterification and transesterification. They make ester links and give off water or methanol. The result is PET resin with the right weight and thickness.

Melting and Extrusion: The PET resin is melted. It is pushed out into thin sheets or films. Sometimes the film is stretched to get the right thickness.

Biaxial Orientation: The film is pulled in two directions. This makes it stronger, more flexible, and better at blocking things. It is good for tough packaging.

Heat Treatment: The stretched film is heated. This removes stress and makes the film stable.

Quality Control: Factories check the film all the time. They test thickness, viscosity, and strength. If something is wrong, they fix it right away.

Tip: The raw materials must be very pure. Terephthalic acid should be over 99% pure for the best PET film.

This process lets makers create different PET film types for many uses. Biaxially oriented polyester film is popular for packaging. It is very clear and strong. Some PET film is made for thermoforming. This is used for hard trays.

PET film is important in packaging. Its special features—like being clear, strong, and resisting chemicals—help protect products and keep them fresh. Being able to recycle PET film makes it even better for the environment.

PET film is special in packaging because it has many good features. These features make it a top choice for many uses. People use it for food, electronics, and more. Knowing about these features helps us see why PET film is so popular.

Clarity is very important for polyester film. PET film is very clear. It lets people see inside the package. This is great for food and store items. PET film stays clear in many situations. It does not get cloudy when used in medical packaging. Clear film is also needed for electronics. Sometimes, stretching the film can make it less clear. This happens because the film changes shape. Still, PET film is one of the clearest packaging materials.

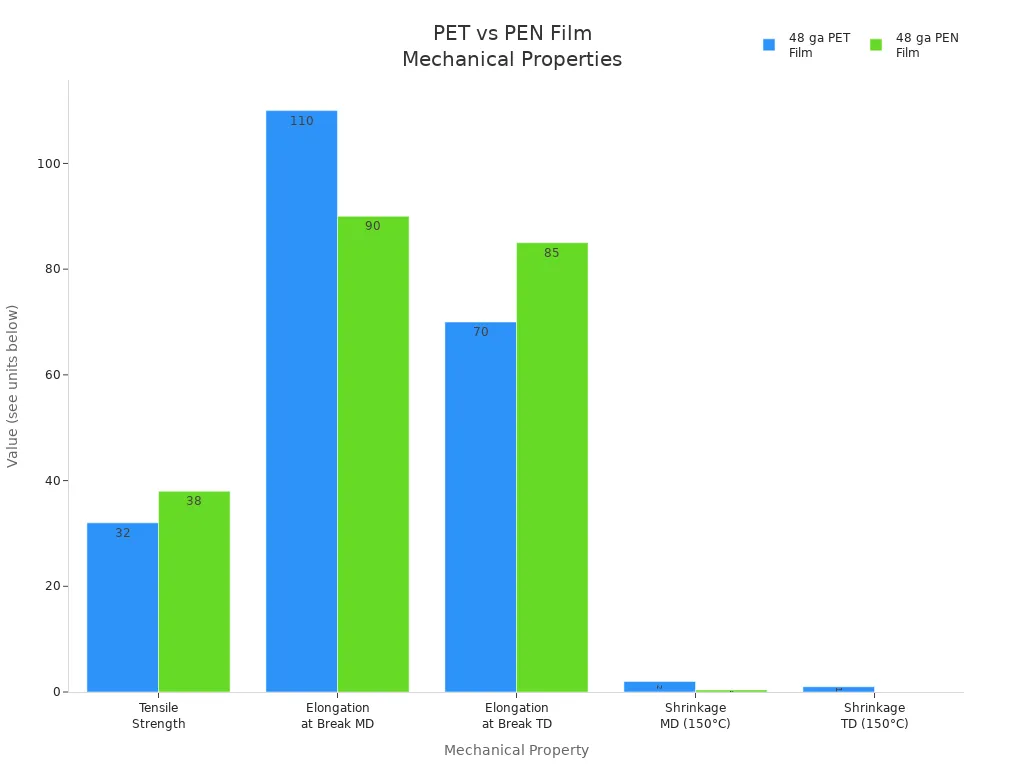

Strength matters a lot for PET film. PET film is strong and does not break easily. It can be pulled and stretched without tearing. This makes PET film last a long time. Packages made from PET film keep products safe. They work well for shipping and storing things. PET film is good for heat-sealed and laminated packages. These packages help keep products fresh. PET film is not as strong as PEN film. But it still protects most products very well.

Property | 48 ga PET Film | 48 ga PEN Film |

|---|---|---|

Tensile Strength | 32 kpsi | 38 kpsi |

Elongation at Break MD | 110% | 90% |

Elongation at Break TD | 70% | 85% |

Shrinkage MD (150°C) | 2% | 0.4% |

Shrinkage TD (150°C) | 1% | 0% |

PET film does not get damaged by many chemicals. It can handle acids, bases, solvents, and water. This means PET film keeps its barrier strong. It does not break down when touching harsh things. In packaging, this keeps products safe and clean. PET film works well with coatings, inks, and glues. This makes it useful for many package designs. Food, medicine, and cosmetic companies use PET film. It helps keep products safe and fresh.

Note: PET film’s chemical resistance makes it great for packaging things that touch strong chemicals.

Barrier properties help keep products fresh and safe. PET film blocks oxygen, moisture, and UV light. This keeps food and other items from spoiling. PET film is used in flexible packaging. It protects things from the air and water.

The tables below show how much oxygen and water vapor pass through PET film:

Film Type | OTR at 73°F (23°C), 0% RH for 1 mil film (cc/100 in²/24 hr) | OTR (cc/m²/24 hr) |

|---|---|---|

Oriented PET (OPET) | 2 - 6 | 31 - 93 |

Film Type | WVTR at 100°F (38°C), 90% RH for 1 mil film (g/100 in²/24 hr) | WVTR (g/m²/24 hr) |

|---|---|---|

Biaxially Oriented PET (Biax PET) | 1.0 - 1.3 | 16 - 20 |

PET film lets very little oxygen and water vapor through. This helps keep products fresh and good for longer.

Thermal stability means PET film can handle heat and cold. PET film melts at about 250°C to 260°C. It works well from -70°C to +150°C. This means PET film is good for hot and cold uses. The glass transition temperature is about 75°C. This helps PET film keep its shape. PET film is used for things that need heat, like sterilizing or hot filling.

PET film is also called Mylar or BoPET. It is very good at stopping electricity from passing through. PET film has high dielectric strength. It resists corona and insulates well. These features stop short circuits. They protect electronic parts. PET film is tough and handles heat. This makes it good for electronic packaging. Makers use PET film to keep devices safe. It stops electrical problems and damage.

Recyclability is a big plus for PET film. PET film can be collected and reused. It helps make new products. This supports green packaging. PET is recycled all over the world. Using PET film helps cut waste and save resources. Many companies pick PET film for packaging. It works well and is good for the planet.

Tip: Using recyclable PET film helps companies meet green goals and attract eco-friendly buyers.

PET film has clarity, strength, chemical resistance, barrier properties, thermal stability, electrical insulation, and recyclability. These features make PET film work well for packaging and industry. PET film sets the standard for strong, safe, and green packaging.

PET film has many good points for packaging. Companies like it because it is strong and saves money. PET is tough and does not bend easily. It can handle heat well. These things help PET film protect products from getting poked or broken. It works even for sharp things like frozen foods or nuts. PET film fits many types of packages, like pouches, sachets, and sealed bags. It is also good for printing and can look shiny, flat, or soft. PET can be used with paper to make clear spots so people can see inside. When compared to PP, nylon, PE, EVOH, or metals, PET is strong, blocks air and water, and does not cost too much. This makes PET a favorite for flexible packaging.

PET film is useful and keeps products safe and fresh while they are stored or moved.

Food and drink companies use PET film for many packages. PET film keeps food and drinks safe from water, air, and germs. This helps food taste good and keeps its texture and vitamins. Studies show that PET film with many layers keeps juice fresh for over a month in the fridge. PET packaging follows strict safety rules to keep food safe and high quality. Some common uses are:

Soft drink bottles

Fruit juice containers

Nut butter and cream jars

Cooking oil and sauce bottles

Covers for prepared meals

PET film helps food last longer and stay good.

Medicine companies use PET film to protect important products. PET packaging stops water, air, and germs from getting in. This keeps medicine safe and helps it last longer. PET is light, does not break easily, and is clear so you can see inside. It can be made to show if someone has opened it or to keep kids out. This helps keep medicine clean and safe. Special ways of making PET make it stronger and seal better. PET film is used in blister packs, single-dose packs, and bottles for sensitive liquids. It can be recycled and follows strict rules, so it is trusted for medical packaging.

PET protective film helps keep surfaces safe during making and moving things. Companies pick this film because it is strong, clear, and stands up to heat and chemicals. PET protective film protects things like LCD panels, touchscreens, plastic covers, and metal sheets from getting scratched or dirty. Many businesses use this film to protect screens in electronics and optics. There are single-layer films for moving items and double-layer films for making things. The film does not tear easily and lets lots of light through, usually more than 80%. PET protective film can handle heat up to 180°C for three days. Workers can put it on and take it off without trouble, and it does not leave anything behind. Some types have coatings that stop static or fingerprints for extra safety. People use PET protective film for phone screens, TV screens, and to protect furniture or appliances.

Tip: PET protective film is better than PE films when you need strong and clear protection for important surfaces.

Factories use PET protective film for many jobs. In electronics, the film keeps motors, transformers, and capacitors safe. PET protective film is good at stopping electricity and handling heat, so it is used for electrical tapes and flexible layers. The film keeps parts safe from water, dust, sunlight, and damage. Metalized PET protective film helps stop electromagnetic problems in sensitive devices. Workers use PET protective film in printed circuit boards and cables. The film works well in hot places and does not rust. These things help electronic devices last longer and stay safe in places with lots of electricity.

PET protective film keeps motor windings and transformers safe.

The film protects printed circuit boards and electronic cases.

PET protective film stands up to chemicals and water, stopping rust.

Metalized types help block electromagnetic problems.

The film stays strong and bends easily in tricky shapes.

PET protective film is used in many other fields. Textile companies use the film to pack and protect their products. Printing businesses use PET protective film for special films and base materials. Medical and health groups like the film because it is safe and stands up to chemicals. PET protective film is used as a base for audio tapes, video tapes, and computer disks. Building and construction companies use the film because it is strong and clear. Companies use PET protective film in glass fiber plastics and precise tools. The film’s many uses help lots of different industries.

Note: PET protective film is a tough, clear thermoplastic polymer made to last and stay clear, so it works well for protecting sensitive surfaces in many kinds of businesses.

PET is known for being clear and strong. It also blocks air and water well. Many companies use PET to pack food, medicine, and electronics. The PET market will keep growing. People want packaging that is better for the planet. New technology helps PET block things even more.

Aspect | Evidence Summary |

|---|---|

Market Growth | Experts think PET use will reach almost USD 11 billion by 2034. Most of this will be for packaging. |

Sustainability Trends | More money goes into making PET that can be recycled or composted. This helps make packaging greener. |

PET packaging makes about 70% less greenhouse gas than other choices.

PET is light, so it uses fewer resources and keeps products from going bad.

PET film is used to wrap and protect food, drinks, and medicine. Companies also use it for electronics, labels, and machine parts. PET film helps keep things safe and fresh.

Coated PET film has a thin layer on top. This layer makes it block air and water better. It can also help with printing or handling heat. The coating lets PET film work well for special packaging and factory jobs.

You can recycle PET film. Many recycling places take PET film. Old PET film can become new packages, fibers, or factory items. Recycling PET film helps cut down on trash.

PET heat transfer film moves printed pictures onto cloth or other things. This film can handle heat and keeps colors bright. People use it for shirts, bags, and ads.

PET reflective film bounces back light and heat. Companies use it in safety clothes, signs, and to keep places warm or cool. This film helps people see better and saves energy.