28 Guihua Road, Zhonglou District, Changzhou,Jiangsu

Views: 0 Author: Site Editor Publish Time: 2025-08-30 Origin: Site

Polyethylene terephthalate (PET) film is a type of polyester film. It is known for being very strong and clear. PET film keeps its shape well and does not stretch easily. It can resist many chemicals and stays stable in heat up to 150°C. PET film blocks out air and moisture well. It is flexible and can be recycled. This makes it good for packaging and many industrial jobs. These special features help PET film keep products safe and fresh. PET film also helps protect quality and safety in many uses.

PET protective film is a good choice for industries that need strong, clear, and tough material.

PET film is tough and clear. It does not get damaged by heat or chemicals. This makes it good for protecting things in packages and factories.

It blocks oxygen and moisture very well. This helps food stay fresh and keeps products safe for a long time.

PET film is used in electronics and insulation. It is strong and protects against electricity. It also stays stable when it gets hot.

PET is stronger, clearer, and handles heat better than polypropylene and polyethylene films.

PET film can be recycled and is good for the environment. It helps lower waste and pollution but still works very well.

PET film has features that make it popular in many industries. These features are strength, clarity, chemical resistance, thermal stability, and barrier ability. Each feature helps PET protective film work well for tough jobs like packaging and electronics.

PET film is strong and keeps its shape well. It does not stretch or tear easily. This helps protect things during moving and storing. PET usually has a tensile strength of 45–55 MPa. It can stretch 70% to 125% before breaking. These numbers show PET protective film can handle stress without breaking or changing shape.

Polymer Type | Ultimate Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|

Polyethylene Terephthalate (PET) | 55 | 125 |

PET film (typical) | ~45 | ~70 |

PET, 30% Glass Fiber-reinforced | 140 | 160 |

PET, 30/35% Glass Fiber-reinforced, Impact Modified | 100 | 110 |

PET film is very clear. It lets more than 90% of light pass through. This happens because the polymer molecules are lined up in two directions. This makes less light bend inside the film. PET film is good for packaging where you need to see the product. It is used for food containers and screens. The film is smooth and has even thickness. This helps keep it looking clear.

Note: Biaxially oriented polyester film is strong and clear. It works well for packaging and displays where you need to see inside.

PET protective film comes in different types for different jobs. Some types are clear, matte, and metallized. These films can be made to have different strength, flexibility, and looks.

PET film does not react with many chemicals found in factories and packaging places. It stays the same when it touches weak acids, alcohols, oils, and some hydrocarbons. This is because of its special polyester structure. PET protective film keeps its strength even after being around these chemicals for a long time.

PET film does not react with most common solvents, weak acids, and alcohols.

Chemicals like toluene and xylene can make PET swell a little at room temperature. The swelling gets worse with heat.

Solvents like chloroform and dichloromethane can dissolve PET at low temperatures, especially if the film is thin.

Alcohols such as ethanol and isopropanol do not affect PET much at room temperature. They may cause swelling with heat or long contact.

Water does not dissolve PET in normal conditions. Silicone coatings can make PET resist water even more.

Strong acids and bases, like sulfuric acid or sodium hydroxide, can break down PET. Do not let PET touch these for a long time.

PET protective film’s chemical resistance makes it good for packaging food, chemicals, and electronics. The film keeps things safe from getting dirty and stays strong in tough places.

PET film can handle high heat without losing its good features. It can be used all the time at about 90°C. This matches its glass transition temperature. Metallized PET films, which have a thin metal layer, can take even higher heat, up to about 112°C. This makes high-temperature resistant polyester film good for hard factory jobs.

Tests show PET film’s glass transition temperature can go up with time, especially in sunlight. For example, it can rise from 74°C to 87°C after being outside for a long time. The melting temperature goes down a little with age, but the film still works well for most uses.

Aging below the glass transition temperature does not change PET much.

Aging near or above this temperature makes the glass transition point higher.

PET can get more brittle after UV light exposure.

Hydrolytic breakdown is small below 80°C, even in wet places, but gets worse above this temperature.

Adding special chemicals can help PET resist water damage and last longer.

PET protective film stays strong and flexible after heat exposure. This makes it good for electronics, insulation, and packaging that faces temperature changes.

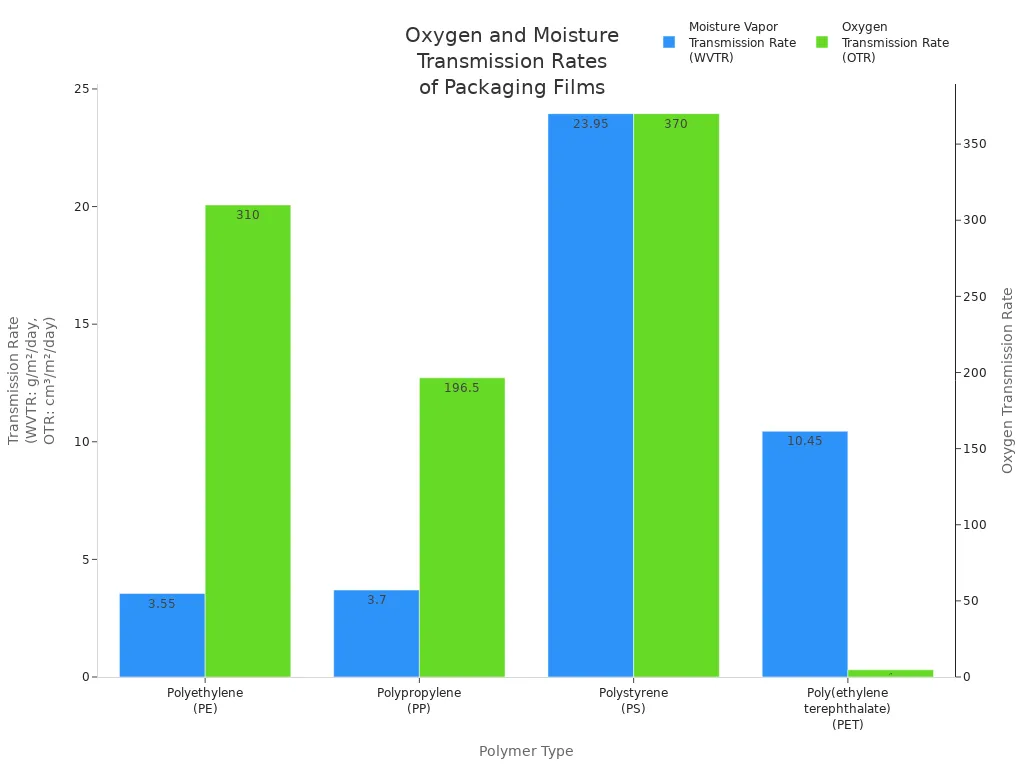

Barrier ability is a big reason why people use PET film. The film blocks oxygen, moisture, and other gases. This helps keep products fresh and safe from going bad.

Polymer | Moisture Vapor Transmission Rate (WVTR) (g/m²/day) at ~38–40°C | Oxygen Transmission Rate (OTR) (cm³(STP)/m²/day) at 20–23°C |

|---|---|---|

Polyethylene (PE) | 1.2–5.9 | 70–550 |

Polypropylene (PP) | 1.5–5.9 | 93–300 |

Polystyrene (PS) | 7.9–40 | 200–540 |

Poly(ethylene terephthalate) (PET) | 3.9–17 | 1.8–7.7 |

PET film lets much less oxygen through than PE, PP, and PS. This means it blocks oxygen better. This helps stop food from spoiling and keeps things fresh longer. The moisture vapor rate is in the middle, but it works well for many packaging needs.

Metallized PET film blocks moisture, oxygen, and light even better. It protects products from fading, losing flavor, and going bad. The film also keeps smells and flavors inside the package. This is important for food and sensitive items.

Metallized PET film stops moisture from getting in or out.

The film lowers oxygen contact, which slows spoilage.

It blocks light and UV rays, keeping color and flavor safe.

The film keeps smells from escaping.

Metallization also makes PET better at resisting chemicals and heat.

PET protective film’s barrier ability helps products last longer and stay good. This makes it a top choice for food packaging, medical tools, and factory parts.

Tip: Picking the right PET film type can make products safer and help them last longer.

PET film works well in many jobs. Its strength, clarity, chemical resistance, heat stability, and barrier ability make it useful. PET protective film can handle tough places and keeps products safe, fresh, and easy to see. There are many types of PET film, like high-temperature and metallized versions. This lets companies pick the best one for their needs.

PET film is important in food and drink packaging. Companies use it to keep food safe and fresh. The film blocks oxygen and moisture. This helps food last longer and not spoil. PET packaging shows if someone has opened it. This makes people feel safe about the food. The film is very clear, so shoppers can see the food inside. This helps people trust the food is fresh and good. Some PET films have many layers. These are used for vacuum-sealed foods. They protect food from air and water. The food industry likes PET because it is light and can be recycled. It also works with new packaging machines.

Aspect | Details |

|---|---|

Market Size (2024) | $15 billion globally for PET barrier films in food and beverage packaging |

Main Reasons for PET Selection | Superior barrier, clarity, lightweight, recyclability, advanced tech compatibility |

Competitive Advantages | Outperforms paperboard and aluminum foil in clarity, recyclability, and barrier performance |

Key Market Drivers | Extended shelf life, product protection, sustainability, regulatory compliance |

PET packaging keeps food safe by blocking germs and keeping it fresh.

Factories use PET film because it is strong and lasts long. The film protects things like chemicals and electronics from light and water. PET packaging must stop oxygen and water vapor from getting in. It also needs to seal tightly. These things help keep products safe when they are shipped or stored. PET film does not tear or break easily. This stops damage and helps goods last longer.

Category | Common Industrial Products Packaged with PET Film | Key Performance Requirements |

|---|---|---|

Industrial | Light-sensitive chemicals, electronic components | Low OTR, low WVTR, strong seals |

Technical | 12μm PET, 12μm VMPET, 50μm PE layers | Cost-effective, durable, high barrier |

Polyester PET film is used in food, drinks, and medicine packaging. In medicine, PET is used for tubing, blister packs, and containers. These keep medicine safe from germs. Medical tools like grafts and test strips use PET because it is strong and safe for the body. PET films are also used for liners in patches and face shields. These uses show PET film helps keep products safe and clean.

Tip: Picking the right PET film helps keep food, factory goods, and medical items safe.

PET protective film is important in electronics. It is used in capacitors because it stops electricity from leaking. This helps devices work well with high voltage. PET film also covers electrical parts to keep them safe. It is thin and bends easily. It protects against heat and stops electric problems. In screens like LCDs and touch screens, PET film is clear and strong. This helps people see the screen and keeps it working for a long time. People use PET film in flexible circuits, display screens, and phone screen covers. PET film does not change shape when it gets hot or cold. This keeps parts lined up right in devices. The film’s low dielectric constant helps with fast signals. This means less signal loss and better device performance.

Property Category | PET Film Characteristics | Contribution to Performance and Reliability in Flex PCBs and Displays |

|---|---|---|

Mechanical Strength | High tensile strength, flexural modulus | Durability and resistance to mechanical stress |

Dimensional Stability | Moderate thermal expansion | Maintains shape and alignment |

Electrical Insulation | Excellent insulation properties | Prevents shorts and maintains signal integrity |

Chemical Resistance | Resistant to alcohols, oils, weak acids | Protects circuits |

Moisture Resistance | Low water absorption | Prevents failures |

Optical Properties | Transparent material | Essential for display clarity |

PET protective film is used for insulation in many places. It stops electricity from going where it should not. This keeps equipment safe from damage. The film can take high heat without melting. It does not shrink or bend in hot or wet places. This helps it last a long time. The film also does not get ruined by chemicals or water. This makes it good for transformers, cables, and other electrical things. PET film is also used to protect screens and TVs. It keeps important parts safe from dirt and water.

PET protective film is used for printing and graphics. Companies use it for making screens, covers, stickers, and labels. The film works well with many kinds of printers. It makes pictures and words look clear and last long. PET film stays flat and does not bend during printing. This is good for making sharp labels and graphics. The film is clear and strong, so it is used for signs, displays, and ID cards. PET film is also used for labels that stick and for printed electronics. It keeps images looking good and working right. People use it for packaging with barcodes, outdoor ads, and store displays.

Tip: PET protective film’s clear and stable surface helps make bright graphics and keeps things safe in many jobs.

Polypropylene film and PET film are both used for packaging. They have some important differences. PET film is stronger than BOPP film. PET can handle more pulling force, from 180 to 250 MPa. BOPP film is less strong, with 130 to 180 MPa. PET film keeps its shape better when used. It also blocks oxygen much better than BOPP. PET lets in only 50 to 130 cc/m²/day of oxygen. BOPP lets in much more, from 1,500 to 2,500 cc/m²/day. This means PET film is better for things that need to stay safe from air, like electronics or medicine. BOPP film is better at stopping water from getting in. This makes it good for things that need to stay dry.

Property | BOPP Film | PET Film |

|---|---|---|

Tensile Strength (MPa) | 130-180 | 180-250 |

Elongation at Break (%) | 50-200 | 70-130 |

Water Vapor Transmission (g/m²/day) | 3-6 | 15-25 |

Oxygen Transmission (cc/m²/day) | 1500-2500 | 50-130 |

Melting Point (°C) | 160-170 | 250-260 |

Density (g/cm³) | 0.90-0.91 | 1.38-1.40 |

PET film can take more heat before melting. It is also heavier and more stable than BOPP.

Polyethylene film is soft and cheap. PET film is tougher and can take more heat and chemicals. In factories, PET film does not stain or turn yellow as easily as PE film. PET film stays strong and clear from -70°C to 220°C. PE film stays soft in the cold but melts in high heat. Both films can be recycled. PET film is picked when people want strong and clear packaging.

Property | PET Film | Polyethylene (PE) Film |

|---|---|---|

Chemical Resistance | Superior; resists staining and discoloration | Good, but less than PET |

Temperature Resistance | -70 to 220°C; high heat resistance | Cold-resistant, less heat resistant |

Mechanical Properties | High strength, stable, clear | Flexible, puncture resistant |

Industrial Applications | Electronics, displays, laminates | Packaging, medical pouches, construction |

PET film is clear and strong, so it is used for packaging and electronics. PE film is soft and keeps out water.

PET film is a special kind of polyester. It is stronger than many other plastic films. It blocks air and water well and does not melt easily. PET film is easy to recycle and helps the planet. Using refillable PET bottles can cut trash and pollution by half. PET film is used in new packaging, electronics, and health care. It keeps products safe and fresh for longer. More companies use PET film because it is good for the earth and works well.

PET film is strong, clear, and good for the environment. This is why many companies like to use it.

PET film is known for being strong and clear. It does not get damaged by chemicals or heat. PET protective film is used in packaging, electronics, and graphics. Many companies pick PET protective film because it lasts a long time. It helps keep products safe from harm. PET protective film is also good for the environment:

PET bottles make half as much greenhouse gas as aluminum cans.

Recycling PET keeps about 53,000 garbage trucks off the road each year.

PET can be recycled over and over, which saves resources.

Property | Benefit |

|---|---|

High strength | Gives good protection in hard situations |

Barrier properties | Helps keep things fresh and safe |

Recyclability | Helps with caring for the planet |

PET protective film helps companies stay safe and protect the earth. Companies should think about using PET film for safe and green solutions.

PET FILM is used in many jobs. Companies use it for packaging and electronics. It is also used for insulation and graphics. Coated PET Film, PET Heat Transfer Film, and PET Reflective Film have special uses.

Coated PET Film gives more protection. It stops scratches and keeps out moisture. This film helps keep food and electronics safe. It also protects medical products during shipping and storage.

PET Heat Transfer Film makes it easy to put images on fabric. It can handle high heat well. This film is good for clothing labels and sportswear. It is also used for custom designs.

PET Reflective Film is used in safety gear and road signs. It is also used for displays. The film reflects light very well. It helps people see better in dark places.

Yes, PET FILM is safe for food packaging. It meets strict safety rules. The film does not react with food or drinks. Many companies pick PET FILM because it is clear and blocks air and water.